In the digital age, innovation doesn’t just happen in labs or on assembly lines—it starts on screens. From detailed architectural designs to cutting-edge medical applications, 3D modeling is reshaping how we envision, design, and produce nearly everything. What began as a tool for animators and engineers has rapidly evolved into a transformative force across multiple industries. One of the most groundbreaking aspects of this shift is the emergence of personalized 3D modeling, where digital models are tailored to individual specifications, needs, or preferences. This capability is not just enhancing creativity and efficiency—it’s fundamentally changing how industries operate and serve their customers.

A New Dimension in Design Thinking

At its core, 3D modeling allows creators to bring ideas to life in a digital environment. Using specialized software, objects can be crafted in three dimensions, manipulated, and viewed from any angle. This capability has revolutionized the design process, making it faster, more flexible, and more intuitive. No longer restricted to flat sketches or static blueprints, designers can now simulate how a product will look and function in the real world, long before it’s physically produced.

This dynamic visualization capability is especially valuable in sectors like product design, architecture, and industrial engineering, where precision and aesthetics must coexist. Designers can experiment with forms, materials, and structures in real-time. Changes that once required days of rework and consultation can now be made in minutes with a few mouse clicks. And with personalized 3D modeling, these designs can be tailored to an individual user—whether that means customizing the fit of a wearable device or adjusting the layout of a modular home.

Healthcare: A Personalized Revolution

Few industries have embraced 3D modeling as wholeheartedly—and with as much impact—as healthcare. Personalized 3D modeling is helping to usher in a new era of patient-centered care. Surgeons now routinely use 3D models of organs, bones, and entire anatomies to plan complex procedures. These models, often based on a patient’s actual MRI or CT scan data, allow for greater precision and fewer complications during surgery.

The power of personalization doesn’t stop there. In the realm of prosthetics and orthotics, 3D modeling enables the creation of customized devices that fit a patient’s body exactly, improving comfort and functionality. In dentistry, digital impressions and 3D modeling allow for crowns, implants, and braces that are tailored to each individual’s dental structure. This shift toward personalized 3D modeling is more than a technical improvement—it represents a paradigm shift toward truly individualized treatment and care.

Manufacturing and Prototyping

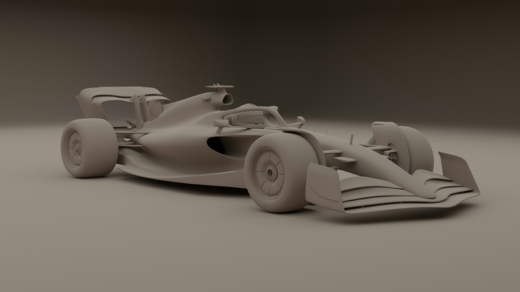

In manufacturing, 3D modeling is the linchpin of modern design-to-production pipelines. Engineers and product designers use it to simulate parts, test tolerances, and identify design flaws long before anything hits the production floor. This capability is particularly crucial in additive manufacturing (3D printing), where the digital model becomes the actual blueprint for fabrication.

With the rise of personalized 3D modeling, manufacturers are now exploring made-to-order products at scale. Imagine ordering a pair of shoes designed precisely for the shape of your feet or furniture custom-fit to your space and aesthetic preferences. As digital customization becomes more seamless, mass personalization—once a logistical nightmare—is becoming an attainable reality.

This agility also opens the door for small-batch production and rapid prototyping. Instead of committing to costly molds and tooling, manufacturers can produce and iterate based on real-time feedback. As a result, the design-to-market cycle becomes shorter and more responsive, giving companies a crucial edge in fast-moving markets.

Architecture and Urban Planning

3D modeling is not just about small products—it’s also reshaping the very spaces we live and work in. In architecture and urban planning, digital modeling allows teams to visualize entire buildings, neighborhoods, or cityscapes before a single brick is laid. These models incorporate not just structural elements, but also environmental factors, lighting conditions, and materials—giving stakeholders a realistic sense of how the final project will perform and feel.

One of the most exciting trends is the use of personalized 3D modeling in home design. Buyers can now walk through virtual models of their future homes, making real-time adjustments to layouts, finishes, and fixtures. These interactive experiences don’t just improve satisfaction—they reduce costly last-minute changes during construction.

Urban planners are also using these tools to create more livable cities. By simulating traffic patterns, pedestrian flows, and public space usage, planners can design smarter, more sustainable environments. In these ways, 3D modeling isn’t just visualizing the future—it’s helping build it, more intelligently and collaboratively.

Media, Entertainment, and Fashion

Unsurprisingly, industries built on imagination and aesthetics have been quick to adopt 3D modeling. In film, video games, and animation, 3D modeling is used to create characters, environments, and visual effects that are both stunning and believable. These digital assets can be easily adjusted, animated, and reused, streamlining production and enhancing storytelling.

Fashion is another area where personalized 3D modeling is making waves. Designers are using digital models to prototype clothing and accessories, experimenting with form and fit in virtual environments. More importantly, some companies are now offering made-to-measure garments based on digital body scans, ushering in a new era of custom fashion that’s both accessible and sustainable. By reducing the need for physical samples and minimizing waste, 3D modeling supports a more eco-friendly approach to fashion production.

Education and Training

The impact of 3D modeling extends into education as well. Whether it’s medical students studying a 3D heart model, engineering students analyzing virtual mechanical assemblies, or history students exploring 3D reconstructions of ancient ruins, the technology brings subjects to life in immersive and interactive ways.

In vocational training and corporate onboarding, simulations created with personalized 3D modeling allow for tailored experiences that match the user’s role, skill level, or environment. For instance, a new hire at a factory can navigate a 3D replica of the plant and practice emergency procedures before ever setting foot inside. These kinds of experiential learning tools not only improve retention but also reduce the risk of costly mistakes in real life.

The Future of Personalization

As artificial intelligence, real-time rendering, and cloud computing continue to evolve, the possibilities for personalized 3D modeling will only grow. Imagine virtual try-ons where you can see exactly how a product fits your body, or virtual environments customized to your behavior and preferences. Combined with generative design—a process where algorithms optimize form and function—3D modeling could eventually produce objects and environments that evolve in response to real-world usage and data.

In many ways, we’re only scratching the surface. The industries mentioned above are just a sample of where 3D modeling is making a difference. As the technology becomes more accessible and integrated with other digital tools, expect to see it revolutionizing everything from agriculture to sports equipment, from fine arts to space exploration.

Conclusion

3D modeling is more than just a digital design tool—it’s a catalyst for transformation across industries. Whether enabling more efficient workflows, more engaging experiences, or more personalized solutions, this technology is changing how we create, collaborate, and connect with the world around us. At the heart of this revolution lies personalized 3D modeling, a capability that puts the power of customization into the hands of designers, consumers, and patients alike. As we continue to embrace this digital dimension, the industries that adapt and innovate will lead the way into a future defined not just by what we build, but how personally we build it.